I designed and make the CNC router mostly to make parts for RC planes and similar out of plywood and balsa wood. This machine is built mostly around previously used pieces of aluminum I had laying around. I don’t have any plans or building instructions for it. I made a fast CAD-design of the machine in SketshUp, but parts of it are improvised as I built the machine.

The wark area is 550 x 300 x 100 mm. This is a good size to fit a standard balsa sheet (100 x 1000 mm) that is cut in half. And the workplace and stick out in both directions. This makes it possible to machine a feature in the middle of a very long piece of wood for example. Of course, I can also load 3 balsa sheets next to each other and let them stick out on one end, and do a lot of wing ribs for example.

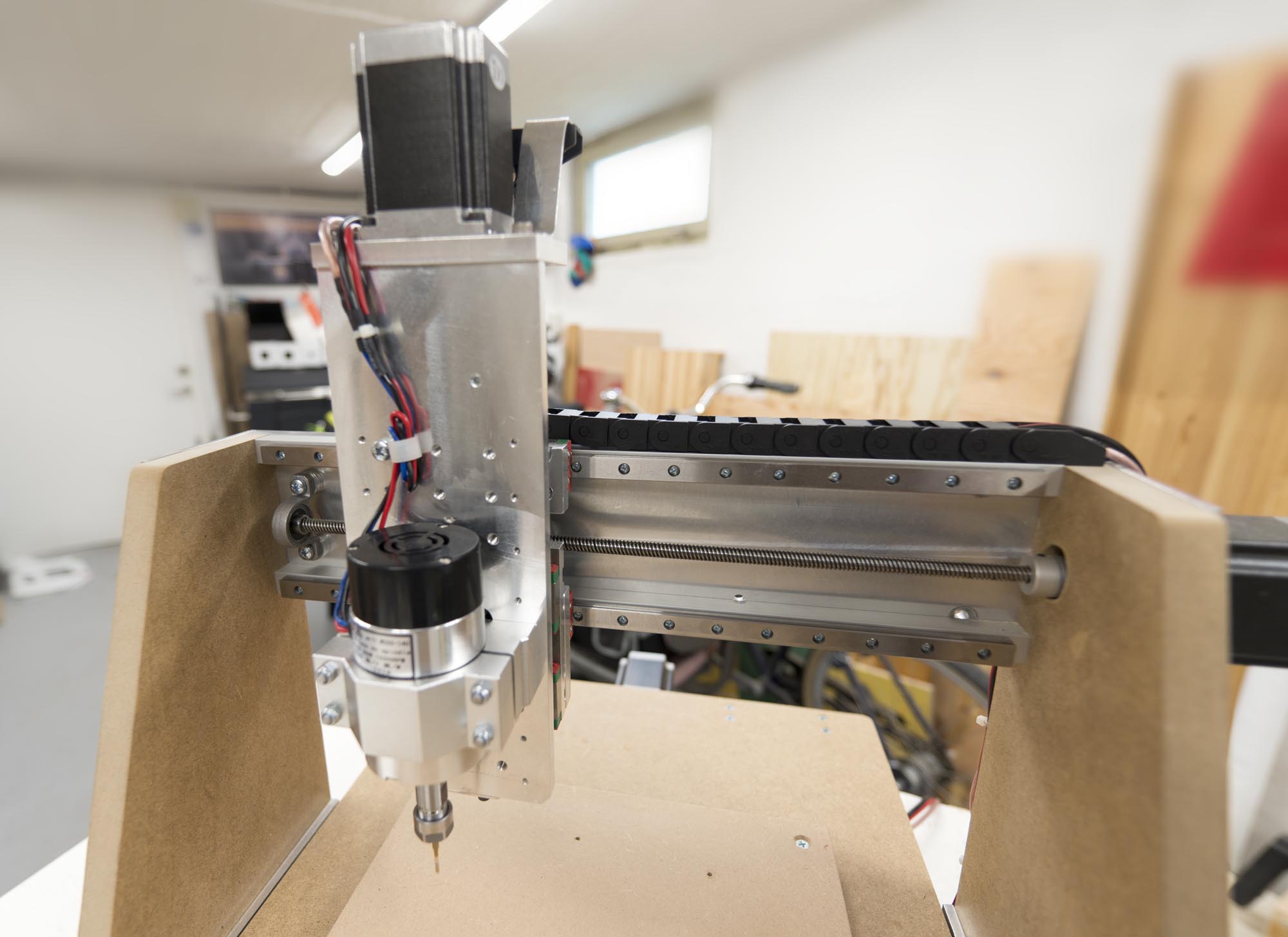

All axis are driven by T8 screws with 8 mm pitch. I use lasting nuts that can be adjusted end tensioned to become close to backlash-free. The two shorter axis, Z and Y, runs on relatively cheap MGN12 linear rails. The longest axis (X) is using even cheaper SBR16 rails and SBR16UU blocks. The MGN12 works really great, but the SBR16 rails do not run as smoothly. Maybe I will upgrade them to MGN12 as well in the future if this becomes a problem. I tried to optimize the cost of the hardware while still not going too cheap and make to machine useless.

The machine is using the three NEMA 23 stepper motors, one for each axis, driven by a Duet 2 WiFi board. I also have the smallest version of the panel-due LCD screen connected to control the machine. I have not installed any end switches. The machine is not powerful enough to damage itself if crash the axis in the ends. I use the touch-screen to manually drive the head to where I want the origin should be for each job before starting it. There is no “homing sequence”.

This video is an overview of the machine, and it also shows machining a few test parts.

In this video, I am using the CNC machine the make a few simple parts that will be used in an RC plane wing.

Below are some images. Click on them to make them larger.